OUR BUNDLED WIRE PROCESS DELIVERS INDUSTRY-BEST LEAD TIMES

WIRE TYPE SELECTION

We start by matching wire type to specifications. Our inventory includes THHN, SIS, XHHW, coax, and data cable, and multiple wire types can be combined in single bundles.

PRINT CUSTOM LEGENDS

Custom legends help avoid on-site labeling and potential errors. After measuring and cutting, conductors are custom printed with critical information or striped, according to specifications.

BUNDLE TO SPECIFICATIONS

Conductors are bundled with a nylon harness in spiral, straight, staggered, twisted pairs, or loose parallel. Footage tape can be added to facilitate measuring or cutting.

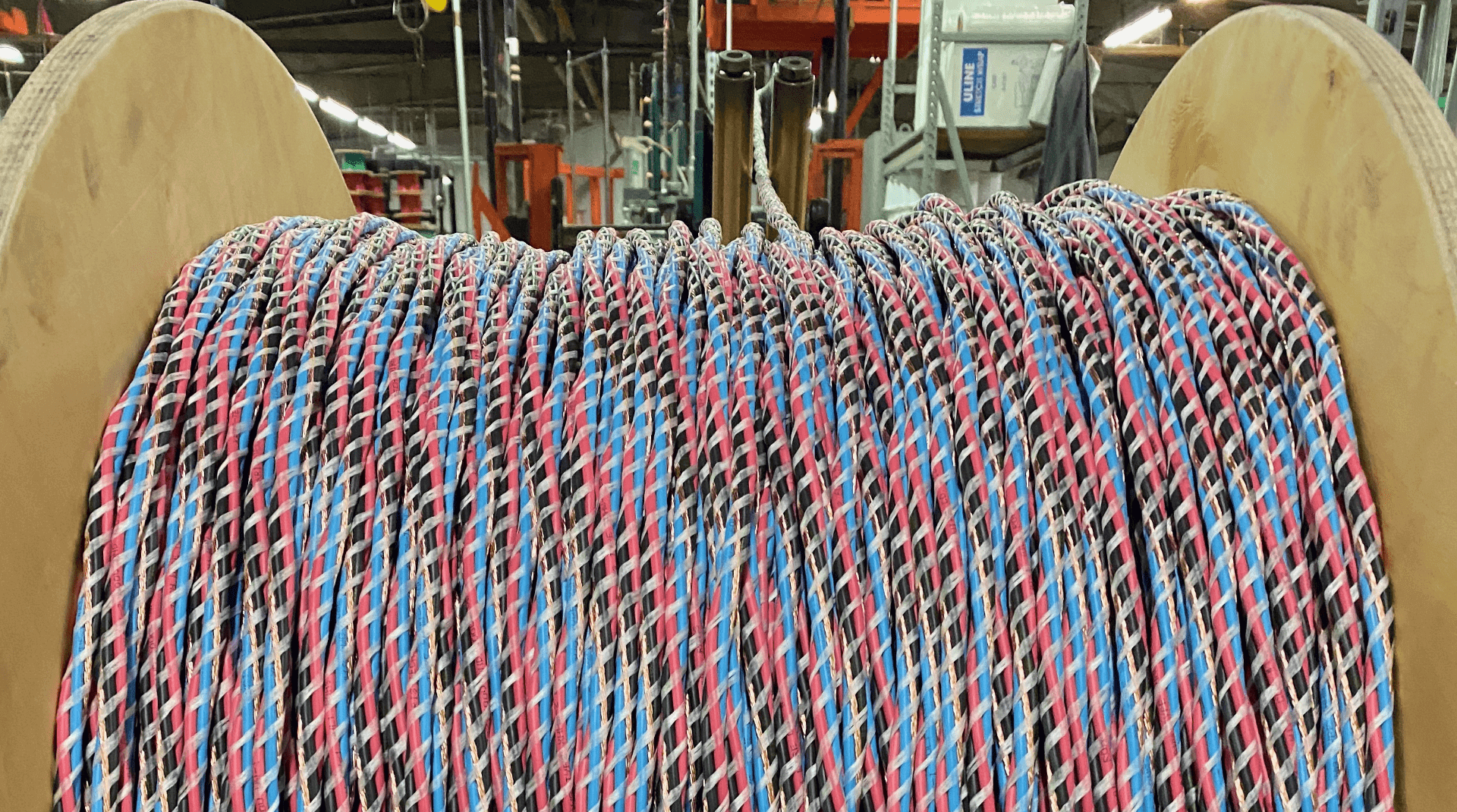

SPOOL TO CUSTOM LENGTHS

Cutting conductors to specified lengths for the project avoids waste and cleanup. Completed cables are matched to spool size to minimize the number of spools and protect them during handling.

COMPARE TO SPEC

Throughout the manufacturing process, bundled wire cables are compared to specification, ensuring wire or cable type, lengths, custom printing and striping, breakouts, and harness types are accurate.

SHIP TO THE DESIGNATED LOCATION

Once final inspections have been completed, finished spools are taken to the loading dock, loaded into enclosed trucks, and shipped to your jobsite.

WATCH THE ONE-PULL PROCESS IN ACTION

WE PULL WIRES TOGETHER, SO YOU DON’T HAVE TO

Electrical contractors waste precious hours pulling and sorting single conductors from multiple reels. One-Pull precuts and labels your wire and cable then bundles it onto one reel – making your job simpler, faster, and more productive.

- Cut to your specifications

- Custom printing

- Shipped on a single reel

- No leftover inventory

- No minimum length requirements

- Made in the U.S.

READY TO SAVE TIME & MONEY WITH BUNDLED CABLE AND WIRE?

Get a quote for our custom wire and cable bundles today.

THE PREFERRED CHOICE FOR ELECTRICAL CONTRACTORS ACROSS THE U.S.

We were able to purchase the One-Pull bundled cable for the same price of all of our previous raw materials, which is a big win with the reduced labor involved.

Chris Piasecki, Chief Technology Officer

We were able to purchase the One-Pull bundled cable for the same price of all of our previous raw materials, which is a big win with the reduced labor involved.