METHODS OF BINDING

One-Pull provides you with the tools you need for the perfect wire bundle solution. Regardless of the industry, intricacy, or size of the pull, we offer everything you need to finish the job quickly and as accurately as possible. Our custom harnesses ensure that regardless of your preferences, or the length of your pull, you can get all your cables and wires from point A to point B and every point in between.

- Bound harnesses are perfect for getting large bundles of wires/cables across long distances without compromising them.

- Cross and spiral laced harnesses bring a tight and secure bundle.

- Cross tape pull tabs allow for staggering end destinations for cables and wires, making it perfect for shorter, more complicated pulls.

- Straight parallel harnesses allow for a tight, secure bundle that can travel across longer distances without an excess of materials in the harness.

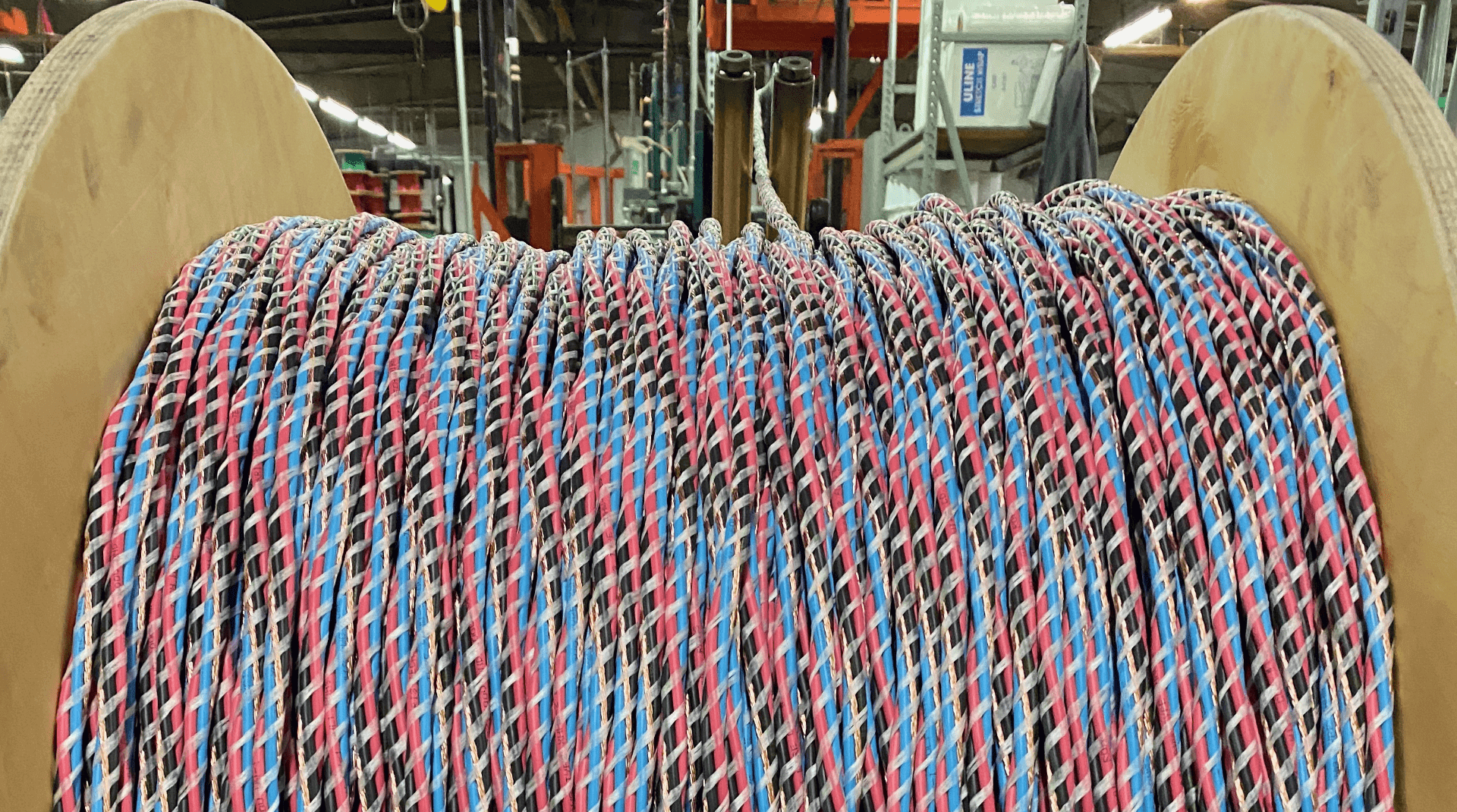

SPIRAL WRAP OR SINGLE BIND

A single strand of industrial thread or tape is used to bind all components together. It is the standard wrap for most spiral configuration cable.

- Available in a strong nylon wax bonded or kevlar binder that lays flat for easy pulling.

- Spiral methods allows for bundles to be cut to varying lengths as needed (must tape either side of the cut) and remain bound.

- Available in varying tightness, and our expert production staff works to ensure that no damage to the wire occurs during the manufacturing process.

- Keeps wire neatly together in a spiral configuration.

- Contractor preference usually dictates its use.

- Normally AWG sizes #18 to #10, limited by a 1.46″ OD, and/or equipment limitations in regards to weight, OD, and reel size.

CROSS LACED

The Double Bind method is the standard wrap for a straight pull configuration cable. Available in a strong nylon wax bonded or kevlar binder that lays flat for easy pulling.

- Double bind method allows for bundles to be cut to varying lengths as needed (must tape either side of the cut) and remain bound.

- Available in varying tightness, and our expert production staff works to ensure that no damage to the wire occurs during the manufacturing process.

- Keeps wire neatly together in a straight configuration.

- Contractor preference usually dictates its use.

- Almost any size wire can be bundled from #18 AWG to #1 AWG only limited by a 2″ OD, and/or equipment limitations in regards to weight, OD, and reel size.

PULL TABS METHOD

Electrical tape with a pull tab is used to bind all paralleled components. This tape is applied every 5 to 10 feet approximately. This method is preferred by some contractors when they feel the spiral wrap is too restrictive and may get hung up in the conduit, raceway, wireway, gutter, or tray.

- Bundles secured by electrical tape every 5 to 10′ depending on the length of the run.

- Tabs are easily removed for a cleaner, faster pull and the conductors move free in the conduit, reducing the number of places the wire catches.

- Conductors can be marked at spacing intervals of 1 to 6″ with up to 255 characters in either black or white ink.

- For bundling #18 to #6 AWG wire up to and over 2″ in diameter, only restricted by equipment limitations for weight, OD and reel size.

- Keeps wire neatly together in a straight or loose parallel configuration.