Spiral Cables Configuration Spec Sheet

Overview

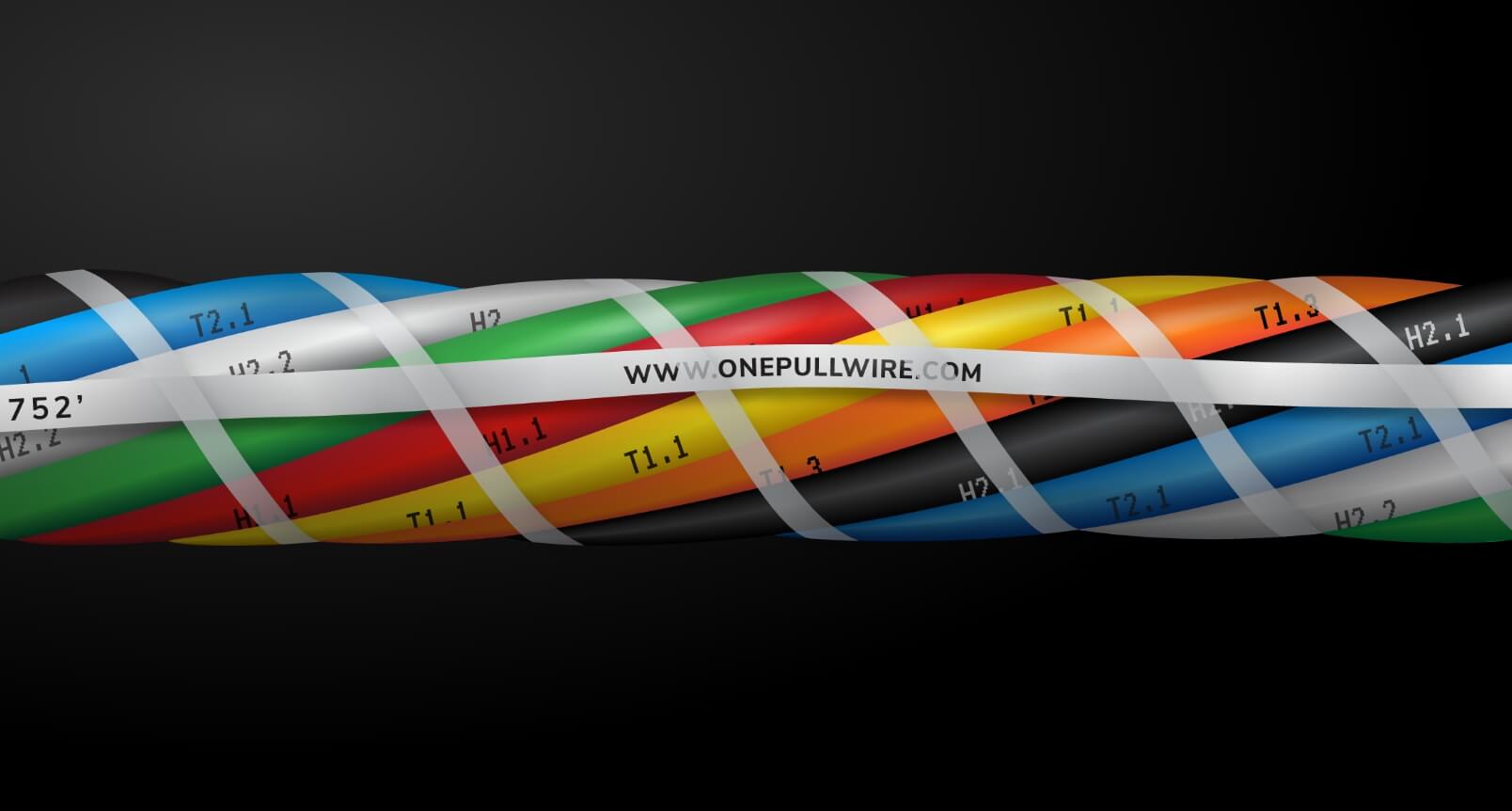

One-Pull is the only bundled wire manufacturer that offers spiral cables configuration, which twists each of the conductors in a concentric lay.

Quik-Pull Spiral is the most flexible custom cable on the market. It retains its roundness and does not change proportion when pulled through 90 degrees. Spiral assembly of building/fixture wire, factory bound, UL labeled and shipped on pull-length reels. Conductors numbered approximately every 1-1/2″.

Industry Uses

- For long pulls in conduit where all the conductors will be carried end-to-end.

- Where minimum outside diameter and maximum flexibility are needed.

- Where the overall assembly is to be jacketed.

SPECIFICATIONS

Conductor

Any combination of electronic, coaxial, twisted pairs, and single conductor. Solid or stranded, bare copper per customer specification. Spiral configuration can be constructed from most single conductor wires, 6 AWG to 18 AWG. Conductor sizes can be mixed in an assembly. Maximum O.D. capability is 1-1/2″.

Insulation

As required by the conductor designation, e.g. MTW, THHN, TFFN, XHHW, plus any electronic cables, e.g. coaxial, low-voltage control, fire alarm. Specification for conductors used will be furnished on request.

Conductor ID

Alpha-numeric characters, words, sentences. Standard sequential number coding. Colors, striping and other alphe-numeric coding available.

Listing

UL Listed Processed Wires. E76139.

Cabling

Unilay spiral construction for flexible finished cable with overall nylon binder thread.

Binder

Two flat, waxed 5040-denier nylon threads, spaced 1″ apart, are wrapped around the entire assembly in the same direction. The waxed binder adheres to the assembly, staying in place while pulling through conduit. Alternative binding and taping are available.

Footage

Sequential footage marker under outer binder thread.

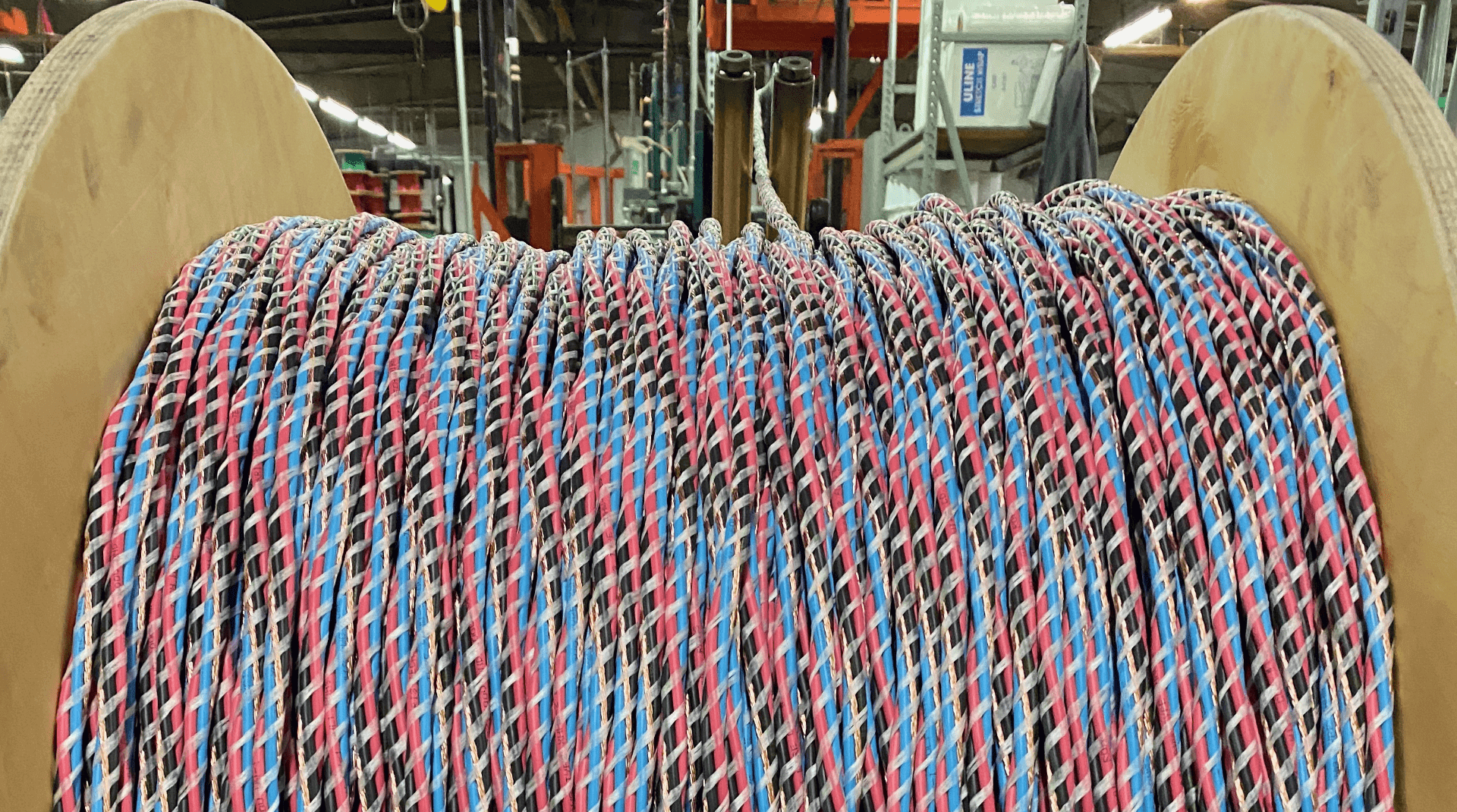

Packaging

No-charge, non-returnable wooden reel. Reel tag contain type, size and beginning and ending sequential footage numbers.