The Value Prop of Pre-Cut, Pre-Labeled, Bundled Cable

Across the wire and cable industry, a common assertion is that bundled, pre-cut, pre-labeled cable solutions can save contractors and installers up to 40% in labor costs.

At One-Pull, we know that assumptions aren’t enough for our customers. So we conducted a controlled time and motion study to quantify the time savings achieved when installing bundled cable compared to pulling, cutting and tagging multiple conductors on-site.

Even we were surprised by the results.

How Does Bundled, Pre-Cut, Pre-Labeled Cable Slash Costs?

Pulling cable is a labor-intensive, multi-step process. Installers must pull conductors from separate spools, feed them through conduit or a cable tray, then label and terminate each wire. Bundled, pre-cut, pre-labeled cable eliminates or simplifies several steps in this process.

Pre-Printed Cable Eliminates Labeling

With single conductors, installers have to label wire multiple times. First, they label individual spools. Next, once they pull the wire through the conduit, contractors separately label each conductor after referencing it back to the associated spool. If they don’t, they’ll need to ring out each wire, a very time-consuming process.

Finally, when installers terminate the conductor onto the breaker panel, they’ll typically have extra wire left over. When they trim that extra wire, often they’ll remove the label as well — so those wires must be relabeled.

Pre-printed cable eliminates the need for all this labor-intensive and time-consuming labeling. With pre-printed conductors, the custom printing repeats every few inches on each wire. No matter where contractors trim and terminate the cable, the identification is always in the right place.

Easier, Faster Pulls

While most of the time savings associated with a bundled cable are realized in both a straight or a spiral configuration, when pulling through conduit a spiral bundle has significant advantages over both singles and a straight bundle.

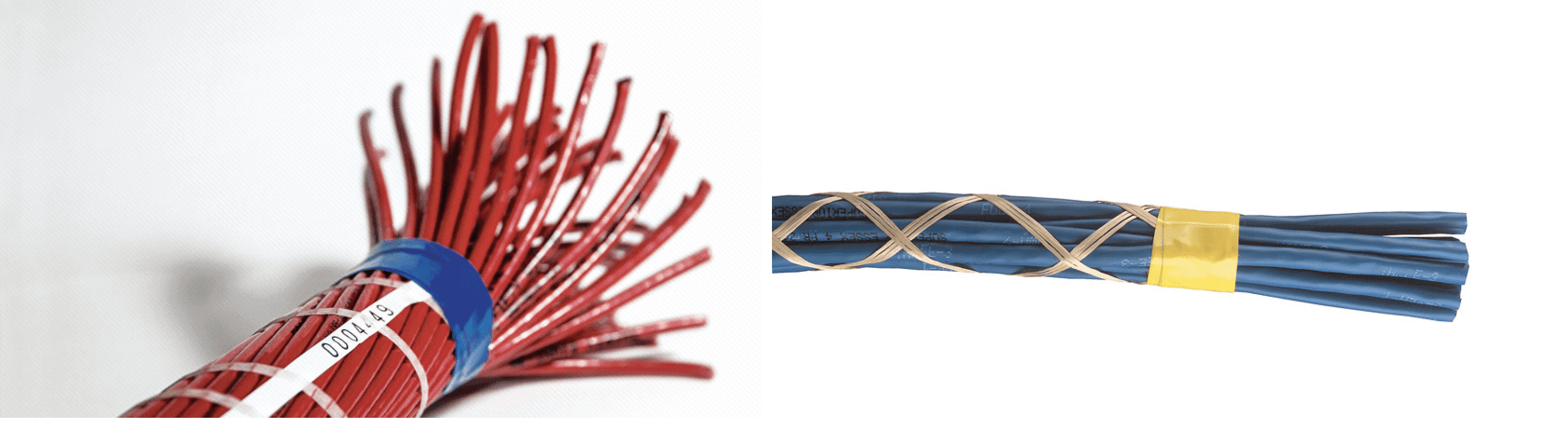

Spiral vs. Straight Cable Bundle Configurations

Contractors often use straight bundled cable configurations for home runs and assemblies laid in place. The un-spiraled structure also helps minimize heat build-up in power wires 12 AWG or larger.

The compact binding in spiral configurations maintains its shape and provides greater flexibility. Spiral cable bundled are often used for long pulls in conduit or where numerous bends in the conduit could cause hang-ups. Spiral-wrapped bundles pull much easier through conduit, requiring much less force.

In our time and motion study, we measured the force required to pull both 50 conductor straight and spiral bundles through the same conduit. The straight bundle needed three people to pull — two pushing from the spool end and one pulling from the terminating end of the conduit. It was slow and difficult to pull — one team member used gloves to help protect his hands when pulling on the pull string to complete the task.

By comparison, the spiral bundle needed only two people — one at each end. The pull required much less effort and was completed significantly faster.

Pre-Cut Cable — Another Time-Saver

When contractors are installing hundreds or thousands of cables, every minute they can save quickly adds up. Pre-cut cables eliminate trimming time for installers and minimize expensive copper waste, both which can yield boost the bottom line.

Other Benefits of Bundled, Pre-Cut, Pre-Labeled Cable

While the cost savings are significant, using bundled, pre-cut, pre-labeled cable offers other important benefits to contractors and installers:

Error reduction

Mislabeling conductors is a serious job site concern. Installers can incur critical delays if they’re forced to ring out or re-terminate mislabeled cables.

Less Cluttered Job Sites

Manually-bundled cables can leave the job site littered with debris — hundreds of empty spools and piles of trimmed cable ends. While a cluttered job site can represent a safety risk, there are also costs associated with disposing of cable debris. Using pre-cut cable also minimizes leftover wire that has no residual value and must be scrapped.

Fatigue Reduction

Contractors are always concerned about repetitive strain injuries and employee safety. Our time and motion study confirmed that it took much greater force to pull manual cable bundles than pre-cut, spiral bundles. These extra efforts can translate into worker fatigue, injuries, and even employee time off.

The Bottom Line — Big Savings

To zero in on the savings potential of bundled, pre-cut, pre-labeled cable solutions, we conducted our time and motion study in a carefully controlled environment. We pulled both 25 and 50-conductor bundles and repeated each step of the process several times.

The result? We determined that contractors using bundled cable solutions is over 8 times faster compared to manually pulling single conductors.

Of course, no two projects or job sites are the same, and not every One-Pull customer may achieve the same results. However, contractors looking to save labor costs and boost margins would be wise to explore the benefits of bundled, pre-cut, pre-labeled cable for themselves.

One-Pull’s lead times are 3-5 days — the shortest in the industry — and our expert customer service team is standing by to answer your questions and provide a same-day quote.

READY TO SAVE TIME & MONEY WITH BUNDLED CABLE?

Get a quote on our custom cable bundles today.